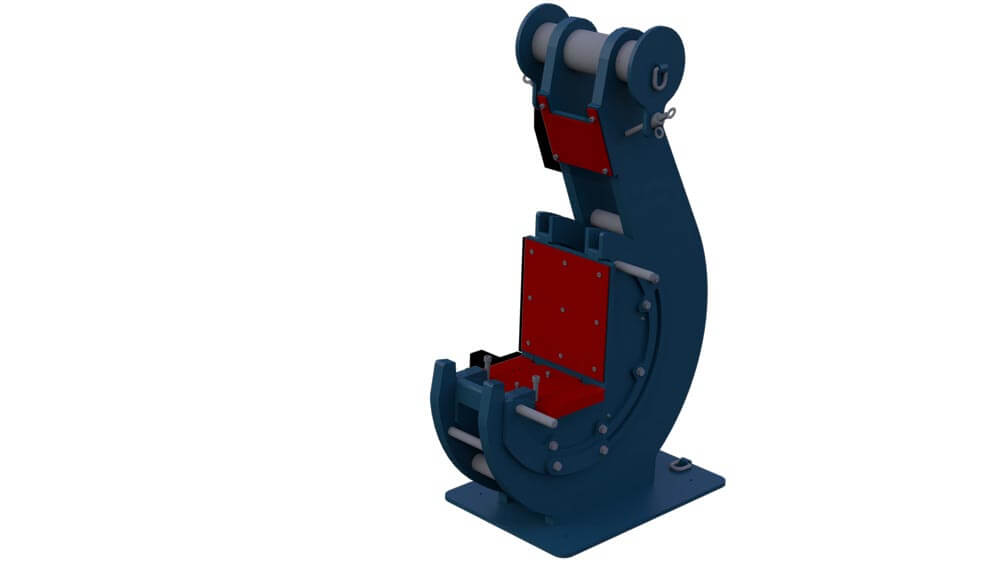

Gentle turning process due to patented inner shell.

Lifting and turning tower segments are the tasks of the newly developed J-shaped hook. During the turning process, the robust safety lug hooks behind the flange. The main innovation is the inner shell with plain bearings (patented), which rotates together with the tower flange during the turning process. This means that no bending forces are introduced into the flange. All contact surfaces are gently equipped with the robust secutex impact protection, the flange lies safely and securely.

The externally positioned pivot point allows the J-Hook to be used on tower flange thicknesses from 60 to 220 mm and heights from 200 to 600 mm.

Considerable time saving

After the lifting / turning process, the J-Hook can simply be removed by crane lift, time-consuming assembly work is not necessary. On the other hand, firmly screwed-on attachment points have to be dismantled after the turning process, which is time-consuming and requires working underneath the load. Working underneath a suspended load is absolutely not permitted, the load must therefore be placed on trestles, which considerably delays the process.

Optional bracing system

With the guy system, even very soft towers can be lifted and turned without deformation.

Images: Vario J Hook